Available in aluminum skin and pontoon, stainless steel skin and pontoon, hybrid skin and pontoon, and full contact

Our IFRs are durable and overcome the many design problems that exist in other well-known brand IFR’s. When the concern is “whole of life cost,” our quality engineered heavy duty IFRs offer tank owners the best possible value for money.

With decades of real-world experience in the design, installation, and maintenance of Internal Floating Roofs (IFRs), Matrix Applied Technologies’ IFRs provide virtually maintenance-free operation of all main structural elements. Our IFRs are custom-engineered to provide optimum performance, even in earthquake prone regions or instances where a tank may be subject to sloshing or high fill rates.

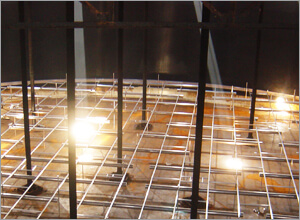

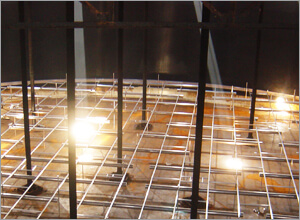

HEAVY DUTY PONTOON INTERNAL FLOATING ROOF

When it comes to quality, performance and value over the life of the asset, Matrix Applied Technologies’ Heavy Duty Pontoon IFR is unmatched in the industry.

- HEAVIER CONSTRUCTION

Our heavy duty IFR construction has an integral structure/frame to which the sheeting and pontoons are added. In contrast to other conventional IFR designs where the pontoons are an integral part of the structure, in the event sheeting or pontoons need to be replaced, the process of replacing sheeting or pontoons on a Matrix Applied Technologies IFR is faster and more efficient.

- LEG CONNECTIONS

Our innovative design eliminates the likelihood of pontoon end cracking, a common phenomenon in light weight IFRs that results from tank turbulence or landing the floating roof during cycling.

- EASY ASSEMBLY, EXCEPTIONAL FIT

Our Heavy Duty Pontoon IFRs come ready to install, with no field cutting required, pre-drilled and pre-punched holes, and flush connections reducing both potential safety issues and installation time. The end result is easy assembly and exceptional fit. Even more, the ease of assembly and tight tolerances reduce installation errors and positively impacts performance.

- LOAD CAPACITY

1000lb/ft2

Our heavy duty IFRs can withstand 1000 lb/ft2, double the standard API 650 Appendix H requirement that IFRs be capable of withstanding a concentrated load of 500lb/ft2.

- STAINLESS STEEL FASTENERS

Matrix Applied Technologies IFRs use only high quality, liquid Teflon coated stainless steel fasteners which provide exceptional resistance to corrosion, durable strength and stiffness.

- SUSPENDING OPTIONS

Matrix Applied Technologies IFRs can be suspended using either cable or chain,providing significant operational advantagesover conventional IFRs with legs.

- EXTRUDED RIM

Matrix Applied Technologies IFRs utilize a heavyduty aluminium extruded rim, making it better able to resist deformation caused by waveaction in the tank as the result of turbulence.

- HYBRID IFR

When product storage requires use of an IFR made from other than aluminium wetted parts, Matrix Applied Technologies’ offers heavy duty IFRs in a Hybrid design with the wetted parts available in either or both stainless steel or anodized aluminium.

STAINLESS STEEL INTERNAL FLOATING ROOF

Our Stainless Steel IFR is the solution when stored product demands the use of 304 or 316 stainless steel for performance and lifespan. The Matrix Applied Technologies stainless steel IFR design and fabrication follow nearly all the same standards, tolerances and features of our Heavy Duty IFRs.

Our Stainless Steel IFR is the solution when stored product demands the use of 304 or 316 stainless steel for performance and lifespan. The Matrix Applied Technologies stainless steel IFR design and fabrication follow nearly all the same standards, tolerances and features of our Heavy Duty IFRs.

- PONTOONS

Matrix pontoons are fabricated from 1.2mm thick stainless steel to conform to API650 Appendix H standards.

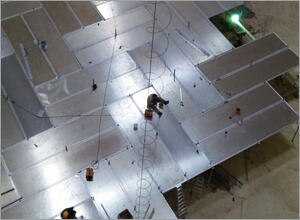

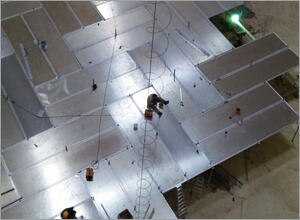

FULL CONTACT HONEYCOMB INTERNAL FLOATING ROOF

Matrix Applied Technologies’ Full Contact Honeycomb IFR is unmatched in the industry.

Matrix Applied Technologies’ Full Contact Honeycomb IFR is unmatched in the industry.

Innovative in both form and function, our precision engineered Full Contact Honeycomb Internal Floating Roof (IFR) eliminates design issues that have historically plagued the industry and still exist with other IFR brands on the market today. Unlike other brands, Matrix Applied Technologies’ IFR allows for increased tank capacity, minimal evaporation, improved fire safety, and extended service life with minimal maintenance.

- PREMIER PERFORMANCE

Matrix Applied Technologies’ Full Contact Honeycomb IFR meets industry standards for low emissions, is designed to allow attachment of a peripheral foam dam system that meets the latest version of fire protection standard NPFA11, and offers a variety of seal options to meet requirements for the product being stored or area regulations.

- SIMPLE ASSEMBLY AND MAINTENANCE

Shipped in either a 20ft. or 40ft. container, our patent-pending clamping method makes assembly, and even replacement, simple and efficient, and our herringbone design provides for added roof strength. All components are designed to pass through a minimum 1500mm x 300mm tank opening. Each honeycomb panel is equipped with a test plug to perform sniff tests during product leak inspections.

- LOAD CAPACITY

1000lb/ft2

Our heavy duty IFRs can withstand 1000 lb/ft2, double the standard API 650 Appendix H requirement that IFRs be capable of withstanding a concentrated load of 500lb/ft2.

- STAINLESS STEEL FASTENERS

Matrix Applied Technologies IFRs use only high quality, liquid Teflon coated stainless steel fasteners which provide exceptional resistance to corrosion, durable strength and stiffness.

- SUSPENDING OPTIONS

Matrix Applied Technologies IFRs can be suspended using either cable or chain, providing significant operational advantages over conventional IFRs with legs.

- EXTRUDED RIM

Matrix Applied Technologies IFRs utilize a heavy duty aluminum extruded rim, making it better able to resist deformation caused by wave action in the tank as the result of turbulence.

Our Stainless Steel IFR is the solution when stored product demands the use of 304 or 316 stainless steel for performance and lifespan. The Matrix Applied Technologies stainless steel IFR design and fabrication follow nearly all the same standards, tolerances and features of our Heavy Duty IFRs.

Our Stainless Steel IFR is the solution when stored product demands the use of 304 or 316 stainless steel for performance and lifespan. The Matrix Applied Technologies stainless steel IFR design and fabrication follow nearly all the same standards, tolerances and features of our Heavy Duty IFRs. Matrix Applied Technologies’ Full Contact Honeycomb IFR is unmatched in the industry.

Matrix Applied Technologies’ Full Contact Honeycomb IFR is unmatched in the industry.